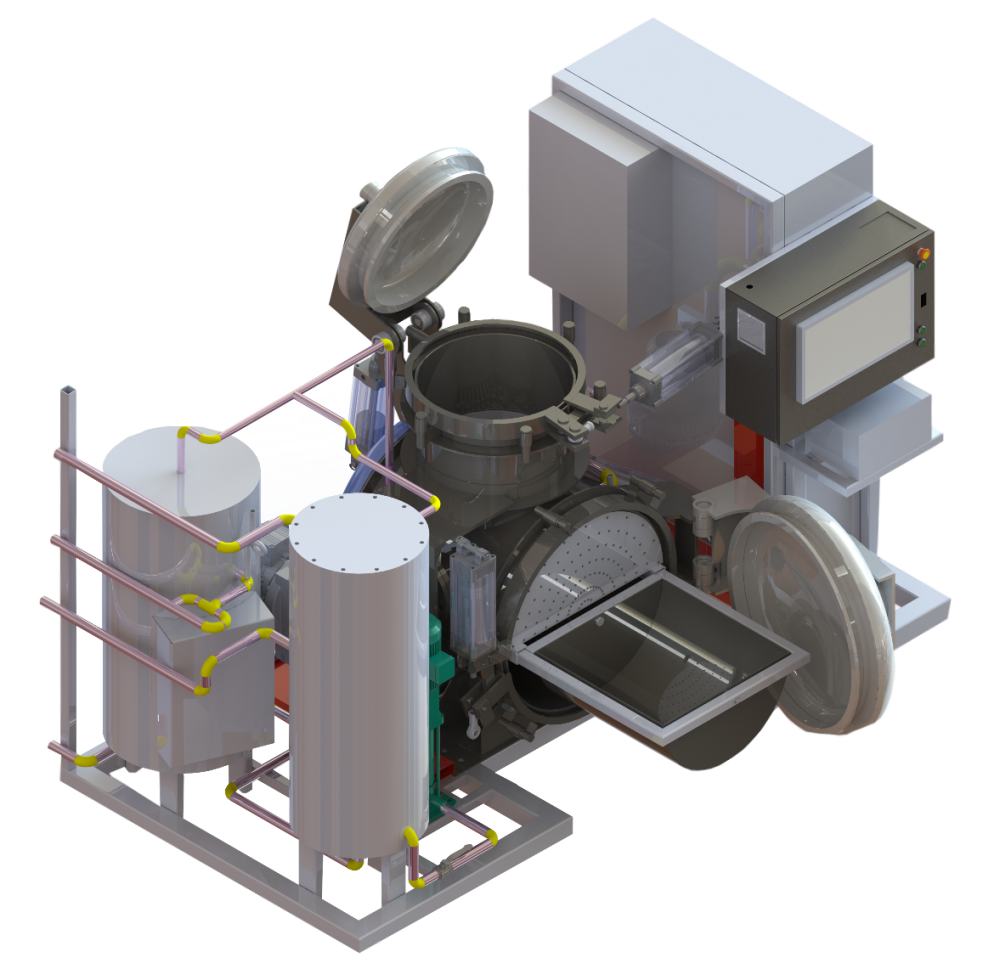

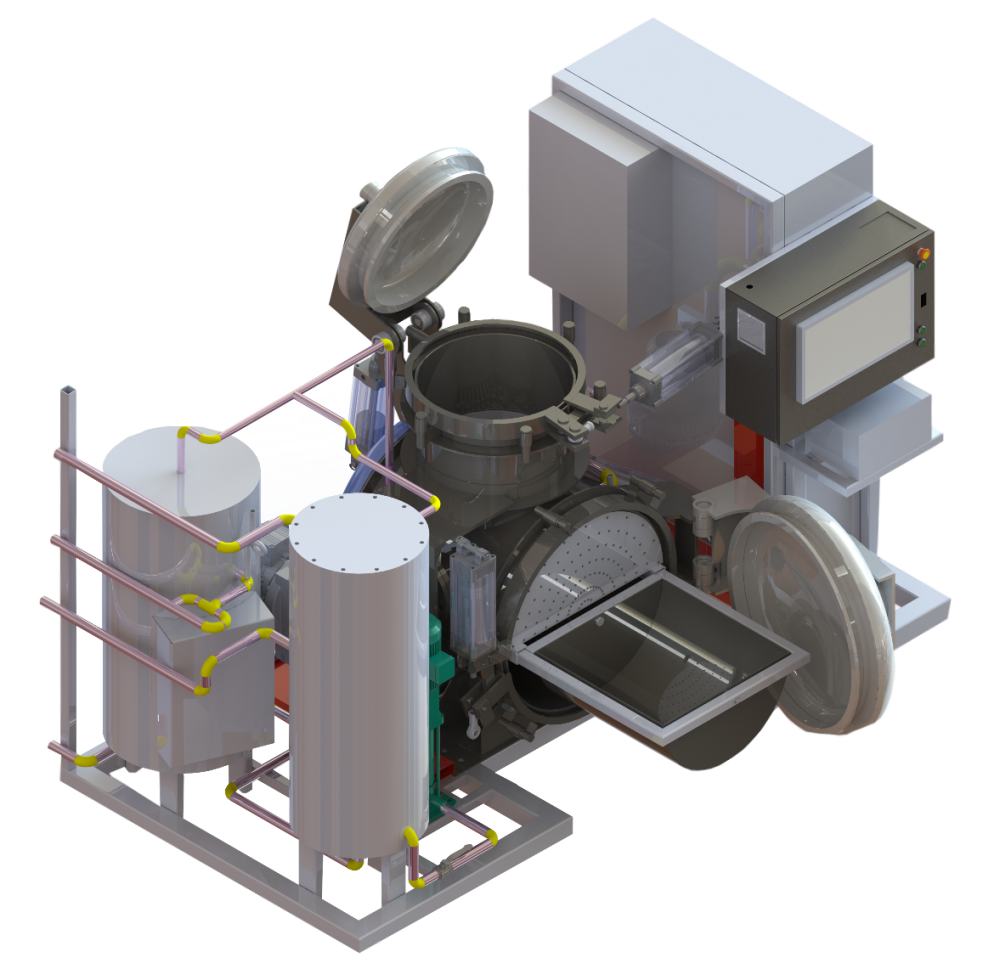

VERTISA - PROMED - MEDICAL WASTE PRE-SHREDDING UNITS : P50 / P100 / P150

_s.jpg)

FIRST SHRED - THEN STERILIZE

FIRST SHRED - THEN STERILIZE

7 different capacity sterilization systems for specific customer needs

- for clinics (P50–P100–P150) and

- hospitals (P300–P500–P1000–P2000)

LOADING

At the beginning of the cycle, once the upper lid opens, the automatic elevator empties the waste in the loading chamber. As the upper lid closes shredding starts.

SHREDDING

The shredder, controlled by the PLC, changes rotation direction due to the “antiblocking” capability that prevents the blades to get jammed. Our special design shredders are capable of grinding very hard materials like surgical stainless steel instruments and hard ceramics. The mixing device in the upper chamber will provide the continuous feeding of the shredder.

HEATING AND STERILIZATION

Heating is achieved by injecting saturated steam until the homogeneous temperature in the upper and lower chamber reaches 134°C (274 F). Sterilization is completed by maintaining 134°C (274 F) - 138 °C (280 F) temperature and equivalent pressure for a period of 10 – 15 minutes. These factors provide the possibility to decrease the pathogenic contamination level in the medicalwasteby8 Log10value.

COOLING AND DRAININGOFCONDENSED WATER

Excess steam in the chamber is removed during cooling phase and the temperature of the grinded sterilized waste is lowered to by injecting cold air in the chamber of the autoclave. The condensed water, that sterile and can be safely discharged into the sewage system is drained with the help of positive pressure or vacuum.

UNLOADING

Once the unloading lid opens and a container is placed below the chamber, the waste trap opens to discharge the sterilized material. As the container is pulled away, the lower lid closes and the sterilizer automatically starts the next cycle.

PROMED P 150 PROMED P 100 PROMED P 50

Size (L x W x H) (mm) 2700 x 1700 x 1700 2700 x 1600 x 1600 2700 x 1500 x 1500

Weight(Kg) 2930 2680 2100

Air Pressure (Bar max) 8 8 8

Electrical connection

required(Kw) 35* 30* 30*

Sterilizing Capacity 45 -55 25 -35 15 -20

(Kg/ Hour)

Process Volume 225 150 75

Capacity (Lt.)

Average Waste 100 -150 100 -150 100 -150

Density (Kg/m3)

Average Cycle 30 30 30

Time (Min.)

Maximum Steam 170 140 100

Flow (Kg/Hour)

Sterilization Efficiency 8 Log10 8 Log10 8 Log10

(SAL)

Steam (Kg) 8 7 6

Electricity (Kw) 1.7** 1.5** 1.2**

Water (Lt) None*** None*** None***

*P50 -P100 -P150 includes built in electrical steam boiler

** Electrical consumption of the sterilizer only

*** Water consumption of integrated steam boiler: 7 -12 Lt./ Cycle

▪ Pressure container built of high quality Stainless Steel

▪ Design and production certified by TÜV Austria

▪ Produced according to EU Directives PED (2014/68/EU) 2006/42/EC, 2014/30/EU&EUNormsEN285

▪ Sophisticated automation control system with advanced reporting and monitoring software

▪ Online access via internet for supervision and troubleshooting

▪ Fully automatic operation-no need for any operator intervention

▪ Automatic elevator system for easy loading

▪ No water consumption

▪ Low fuel and electrical consumption for integrated steam boilers equipped with state of the art steam regeneration system

▪ Turn Key solutions by providing Steam Boilers, Shredders, Container Washers, Compactor Systems designed and manufactured in house for a complete solution.

▪ Multiple safety control devices and built with highest safety standards Design and manufacturing with international standards including CE, ASME,EAC(GOST-R)

More products from this supplier

- United States

- United States

- United States

Loading...