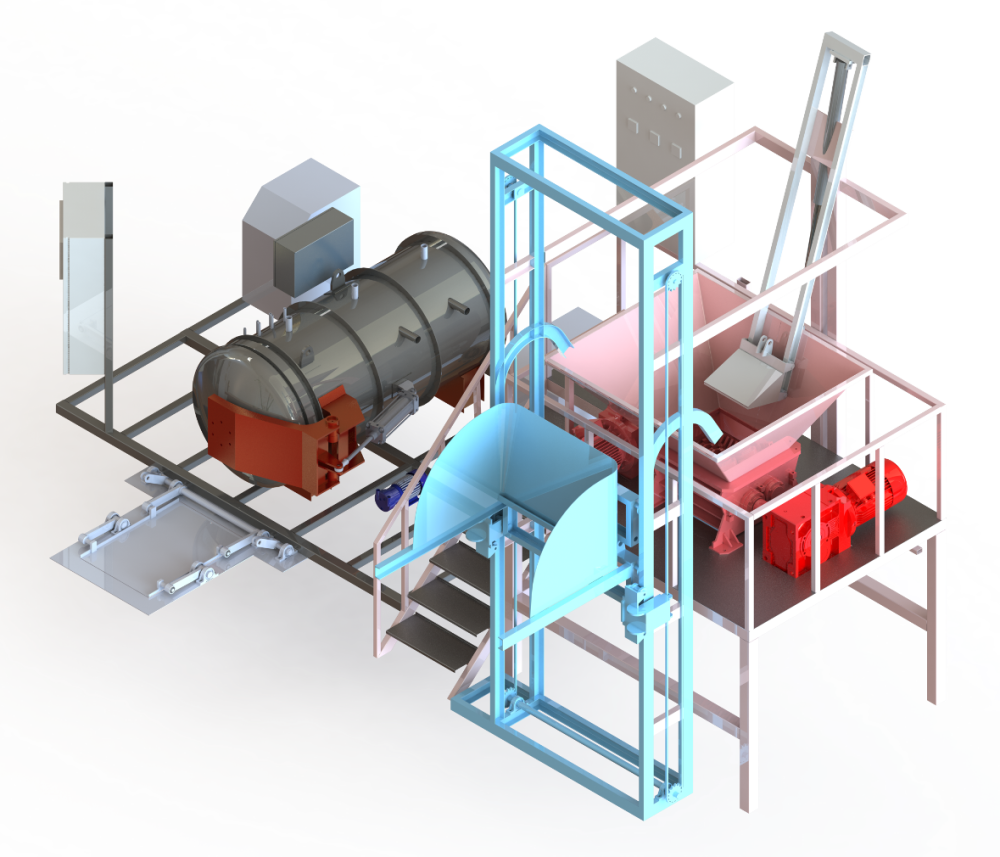

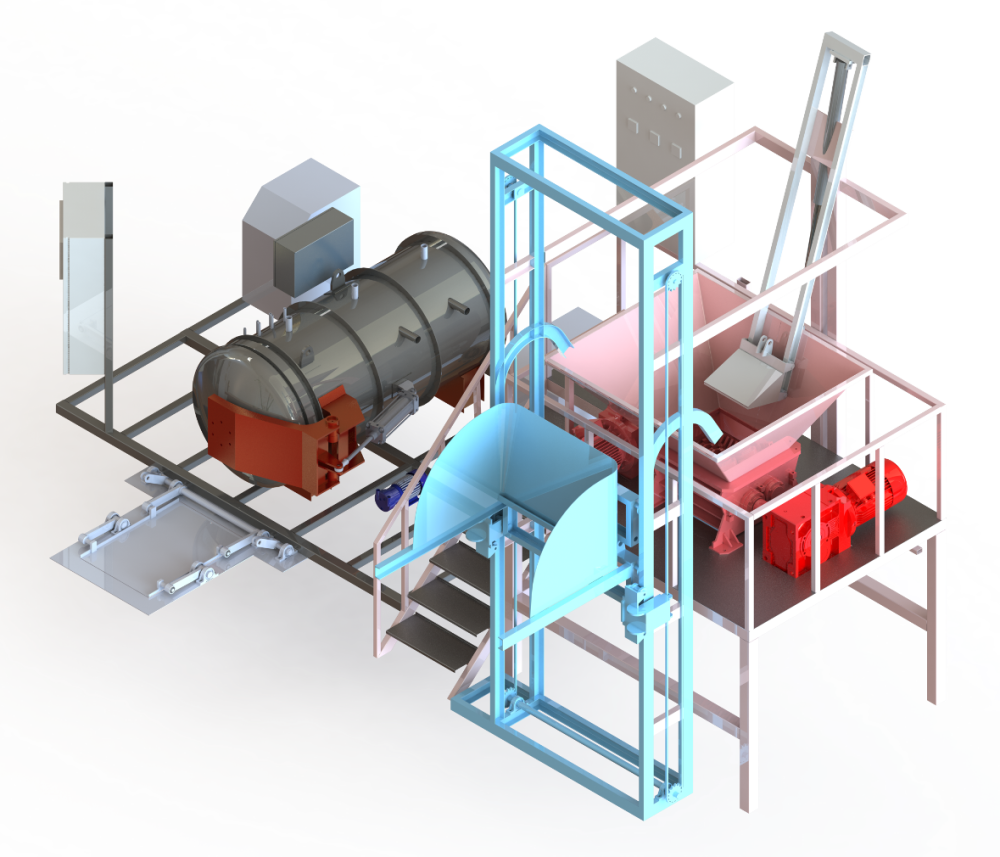

VERTISA PROMED - MEDICAL WASTE POST-SHREDDING UNITS

FIRST STERILIZE–THEN SHRED

▪ 5 different capacity sterilization systems for specific customer needs for clinics (A 75 – A 150) and hospitals or industrial sterilization facilities (A300–A500–A1000)

LOADING Stainless steel autoclave carts filled with waste are loaded into the automatic amp and then pushed into the autoclave. As the loading is finished the ramp lowers and the loading lid closes.

HEATINGANDSTERILIZATION

Heating is achieved by injecting saturated steam until the homogeneous temperature in the chamber reaches 134°C(274F).The chamber is vacuumed and heated 3 times until all the air is replaced by saturated steam in order to achieve the perfect sterilization condition. Sterilization is completed by maintaining 134°C (274 F) - 138 °C (280 F) temperature and equivalent pressure for a period of 10 – 15 minutes. These factors provide the possibility to decrease the pathogenic contamination level in the medical wasteby8Log10value.

Excess steam in the chamber is removed during cooling phase and the temperature of the sterilized waste is lowered to by first vacuuming and then injecting cold air in the chamber of the autoclave. The condensed water, that sterile and can be safely discharged into the sewage system is drained with the help of positive pressure or vacuum.

UNLOADING

Once the unloading lid opens and the automatic ramp elevated, the autoclave carts with sterilized waste are removed from the autoclave. Loading of the new batch can be completed and start a new cycle immediately.

SHREDDING

The autoclave carts with the sterilized medical waste are loaded into the automatic elevator that will empty the waste on the shredder. The shredder, controlled by the PLC, changes rotation direction due to the “anti blocking” capability that prevents the blades to get jammed. Our special design shredder is capable of grinding very hard materials like surgical stainless steel instruments, glass, hard plastic, thin metal sheets and hard ceramics. A hydraulic ram will force the waste on the blades to provide the continuous feeding of the shredder.

▪ Pressure container built of high quality Stainless Steel

▪ Design and production certified by TÜV Austria

▪ Produced according to EU Directives PED 2014/68/EU, 2006/42/EC, 2014/30/EU&EUNormsEN285

▪ Simultaneous Shredding and Sterilization process for higher capacity output

▪ Automatic loading and unloading ramp for the autoclave carts

▪ Sophisticated automation control system with advanced reporting and monitoring software

▪ Online access via internet for supervision and troubleshooting

▪ Fully automatic operation-no need for any operator intervention

▪ Automatic elevator system for easy loading

▪ No water consumption

▪ Low fuel and electrical consumption for integrated steam boilers equipped with state of the art steam regeneration system

▪ Turn Key solutions by providing Steam Boilers, Shredders, Container Washers, Compactor Systems designed and manufactured in house for a complete solution.

▪ Multiple safety control devices and built with highest safety standards Design and manufacturing with international standards including CE, ASME, EAC (GOST-R)

More products from this supplier

- United States

- United States

- United States

Loading...