HealthManagement, Volume 12 - Issue 4, 2012

Safety may be defined as the condition of being safe from injury or loss. Safety in any field is a dynamic and continuous course of action involving hazard detection and correction.

Healthcare professionals need to keep abreast of technological advances, their limitations and risks by carefully examining the risks finding the most effective workable solutions to manage them.

In order to achieve this goal the 3A principle applies:

- Awareness of the problem;

- Analysis of the problem;

- Action plan with corrections.

Hospital safety encompasses human, machine and environmental elements. There should be a systems approach to understand the mechanisms contributing to accidents involving medical equipment. This approach will identify the causes and accordingly solutions to minimise subsequent accidents can be suggested. The imaging department must be designed with safety in mind.

Design of the Imaging Department

A dedicated engineering approach is required to ensure effective planning and design of the department, taking into account workflow, patient comfort, and prerequisites required for installation of the imaging equipment.

The location of the individual modality should be pre-planned. The room layout plan should indicate the electric supply points, data points, door dimensions for safe patient entry into the room, location of medical gases outlets, air conditioning with high efficiency particulate air (HEPA) filters and so on.

As far as possible the modalities giving ionizing radiation should be planned on one side of the imaging department and the non-ionizing type such as MRI and ultrasound on the other side to reduce radiation hazards.

For MRI installation special care should be taken in designing the RF cage. The surrounding area of this modality should not have installations of multi-parameter monitors or other sensitive devices whose performance is affected by magnetic field.

Since most of the modern imaging equipment designs are incorporating recent advanced electronic circuits, they should be protected from dust, humidity and temperature variations. This can be achieved by air conditioning the installations.

Heavy floor mounted units such as CT scanners, catheterization laboratory, MRI, PET scanners, linear accelerators and so on require a weight-bearing floor with adequate foundation. The equipment should be mounted on a base plate only with desired mounting anchor fasteners as specified by the manufacturer of the equipment after the curing time for the foundations is over. Any shortcuts will result in vibrations of the unit during its operation and compression art facts in image, resulting in poor image quality, repetition in diagnostic tests, leading to eventual reinstallation of the unit.

Prerequisites such as height clearances and provision of mechanical supports for preventing sags of the beams should be complete before bringing the unit to the room allotted to avoid damage of equipment due to environmental factors such as dust. Installing such equipment requires special skills and this task should be entrusted to the vendor.

In summary, the prerequisites for installation of imaging department equipment are:

- Electric power supply;

- Back-up power source such as a diesel generator or uninterrupted power supply;

- Proper earthing;

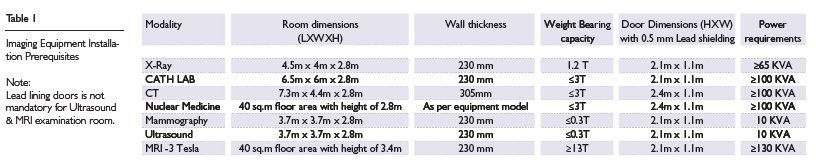

- Room layout with proper shielding/ wall thickness especially for ionising radiation equipment (see table 1);

- Weight-bearing capacity for floor mounted or ceiling mounted systems;

- Temperature and humidity control with proper location of air conditioning ducts;

- Adequate room lighting;

- Emergency off switch.

These aspects should be discussed in detail with the vendor and prepared before arrival of the equipment in hospital. In case of variations, appropriate corrective action should be taken well in advance before the equipment arrives in hospital. These prerequisites may vary from model to model from different vendors. Any shortcuts or omissions may prove to be very costly as well as hazardous.

For ionizing radiation equipment prior approval from the respective controlling authority as per ICRP regulations is mandatory. This involves approval of the room layout plan, wall thickness, door dimensions and shielding.

Electricity

Micro shock current results from leakage current, which passes from an equipment metal chassis to the ground. When it passes directly through the heart of a catheterized patient, it causes ventricular fibrillation and possible death. Steps to prevent accidents include providing equi potential grounding to ensure that all conductive surfaces in the room are bonded together and to earth.

The earthing terminal should have proper marking, corrosion proof parts with a smooth finish and no burr of the equipment housing so that if by accident a live wire touches the housing chances of damage to insulation are eliminated and corona discharge can be avoided.

Flexible cables should be used to interconnect different modules with adequate insulation, properly bunched together and routed through a single opening in metal walls of housing with an insulated washer or enclosure

Live parts should be properly secured with desired spacing between the live electrical connection and enclosure so that they are not shifted from their desired position during transportation or vibrations.

For mobile C-Arm image intensifiers trolley wheels should be of conductive rubber material to ensure passage of any discharge to the ground.

Protection against voltage exceeding 40 Volts RMS during normal equipment working should be avoided by laying down conductors away from the chassis and by providing adequate insulation.

Metallic components which do not form part of the operating circuit of installation and equipment operating at rated voltage above 40 volts should be properly earthed if they are likely to come in contact as a result of faults or arcing with components at high voltage. Leakage currents: This is important and especially in case of medical devices which are in contact with the skin of the patient.IEC 60601 specifies limits for leakage currents.

Leakage currents increase with longer mains cord. Incorporating safety measures in designing equipment to prevailing standards (International Electro technical Commission - IEC 60601) will ensure electrical safety for patients and end users.

In general, care should be taken to avoid causes of electric shock such as careless use of electricity, faulty electric cords, appliances, sockets, faulty designs, use of extension cords, poor grounding and lack of knowledge about applications and use of equipment.

Magnetic Field Safety

Magnetic field safety is applicable to MRI installations. Care should be taken to shield the magnet and procedure room from external magnetic interference; ensuring radiation levels specified are not exceeded.

The MRI equipment should not allow RF deposition on patients beyond specified limits. All specific precautions against magnetic radiations should be observed. For protection against fire, the tanks should be cooled with water jets.

Maintain the desired minimum clearances from the objects, such as water cooling systems, wheel chairs, carts, transformers, overhead power lines, vehicles including cars and trucks trains etc., as specified in the installation prerequisites supplied by the manufacturer to ensure trouble free performance of the magnet.

Radiation Protection

Non-ionizing radiation is a significant health hazard in hospitals; it includes ultraviolet, radio wave, infrared, and microwave and laser radiation. Since the eye is most susceptible to damage from these types of radiations due precautions should be taken during usage of such devices. This is of utmost importance while using laser or microwave devices.

Interlocks should be provided for protection against radiation in the event of removal of covers and shields of the unit.

An extensive radiation safety programme is essential to ensure that equipment meets acceptable performance and safety standards. It has been observed that a large percentage of accidents and incidents relating to these types of equipment are mechanical in nature and are not related to radiation injury.

X-Ray and Nuclear Medicine Equipment

Ionizing radiations produce biological effects and are harmful to human tissues

Protection measures:

- Use radiation exposures only when necessary and justified;

- Keep maximum distance from source of radiation;

- Reduce exposure time to minimum required;• Improve shielding with lead lined screens;• Provide an emergency off switch;

- Ensure that all protective ground wires are connected properly;

- The connection between covers and protective ground wires must be made with screws and lock washers, thus eliminating possibility of all metallic covers which may develop a dangerous voltage in the different components of the equipment;

- Use image intensifier television chain with high power DC x-ray generators to reduce exposure to soft radiation;

- Follow ICRP recommendations for a system of dose limitation;

- The room layout plan should have approval from the regulatory authority.

Equipment offering high frequency has almost zero ripple factor which gives 60% higher radiation dose yield as compared to two pulse X-ray generator and low skin radiation dose, shorter exposure times leading to reduction in kinetic blurring and improvement in image quality. Additionally these type of generators are of smaller size and lower weight, microprocessor controlled with consistency in exposures even at variable mains input ideally suited for the modern imaging department.

Human Factors

Risks associated with diagnostic medical equipment often relate to data inputs, manipulation and display. Risks are directly related to the quality and limitations of diagnostic data obtained by the equipment. To avoid these issues it is imperative that proper training programmes are planned by hospital authorities when new equipment with advanced technology is purchased so that technicians are well trained in advance.

Over the last century many accidents have been witnessed due to adopting short cuts in designing, manufacturing, transporting, installing and using equipment. For example, during transportation of a mobile x-ray unit from one ward to another, care should be taken to park the tube head at the lower end of the trolley for mechanical stability.

Many accidents have taken place when precautionary measures were not taken, resulting in injuries and damage to sensitive parts of the unit, thus incurring heavy expenditure. Failures such as the fall of the x-ray tube head due to breaking of wire ropes, or patient‘s fingers fractured when they were caught between the moving edges of x-ray table or injury to patient while undergoing x-ray examination when the cable hanger dropped and struck in the face were very common.

In order to overcome such a situation the following safety factors should be incorporated:

- The mechanical strength of wire ropes should have a safety factor of 6 (i.e. if a wire rope is carrying a weight of 1 Kg then it should not give way for load of 6 Kg)

- The mechanical installation should have a safety factor of 2 to 3;

- There should be no compromise in specifications for anchor fasteners etc. by providing lock nuts and/or spring washers which carry heavy assemblies. Lock nuts or spring washers ensure that assembly when mounted on a platform does not get disengaged due to vibrations. This is very important in case of mobile units, scanners using moving assemblies such as those in gantries etc.

Maintenance

This comprises the performance of non-functional repairs, component or assembly replacement, frequent cleaning and general servicing in order to prevent improper or inadequate operation. Maintenance helps to prevent failures due to malfunctioning of the equipment and extends the total life span of the equipment. For major equipment like CT, MRI or PET scanners calibration at regular intervals is necessary to maintain their throughput. Calibration is the assessment of equipment performance as mentioned in respective standards of that equipment.

Maintenance can be preventive or corrective. There is a subtle difference between the two. Preventive maintenance involves routine inspection and testing at regular intervals while corrective maintenance involves total calibration and replacement of defective parts. These measures can reduce hazards by uncovering early signs of degradation.

Following the functional testing of any equipment a sticker should be affixed to the equipment describing serial number, location of equipment, the date of maintenance, person involved and next date of maintenance. A separate ledger should be kept recording all the steps taken, parts replaced and duration of the process. This process will help to determine the economical viability of the equipment. A general rule is that when the depreciated value of the equipment is comparable to repair and maintenance costs, the equipment needs to be replaced. The overall life span of equipment is around seven years for electronically-based equipments.

Conclusion

When an imaging department is planned, recently developed products with their requirements must be taken into consideration. A technically upgraded, scientifically planned and designed department with due importance paid to safety aspects will guarantee effective medical care.

Anil Nilkanth Shastri is Consultant, Equipment Consultancy Group, HOSMAC India Pvt. Ltd., Mumbai, India