Transforming care delivery in a single department

or an entire healthcare enterprise.

Executive Summary

Digital twin technology has proven its value in manufacturing, where use

of connected technology to monitor performance, model processes, and

optimize efficiency is already a mainstay of “Industry 4.0”. The link between

the physical and virtual worlds is a key facet of this emerging manufacturing

paradigm. Now, through the efforts of multi-disciplinary teams, hospitals are

creating four-dimensional digital twins of patient care units. They’ve realized

the value of running “what-if” scenarios for optimizing departmental

operations.

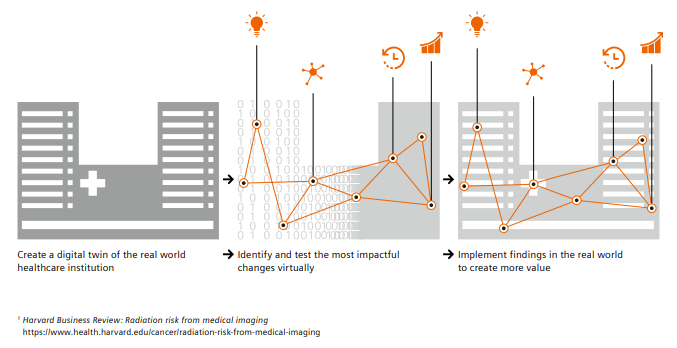

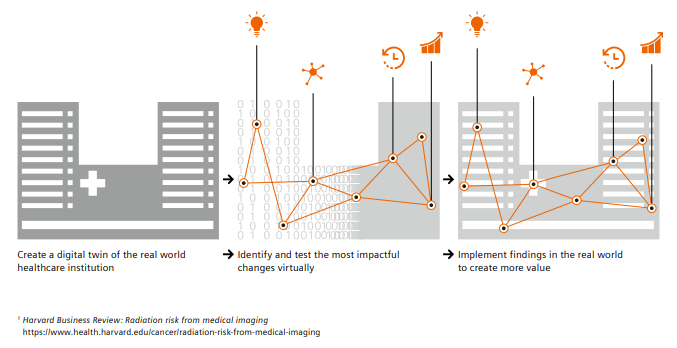

A digital twin can help healthcare enterprises identify ways to enhance and

streamline processes, improve patient experience, lower operating costs, and

increase higher value of care. The digital twin creates models of physical

spaces and processes. Then, cost and quality optimization parameters are

examined and ultimately selected based on the insights gained from

simulations leveraging the digital twin. Digital twins insights can be further

enhanced with complimentary technologies like Real-Time Locating Systems

(RTLS), which provides a robust data source and a means to test changes in

layout, process, etc.

A digital twin can have tremendous real-world impact. Mater Private Hospital

in Dublin, Ireland partnered with Siemens Healthineers to create a digital

twin of its radiology operations. The identified improvement potential was a

nearly half-hour reduction in patient waiting time, and significantly reduced

staff overtime costs.

The key to success of a digital twin is a strong partnership between the

hospital and a technology provider who understands the clinical, workflow,

and financial imperatives of healthcare providers. Siemens Healthineers

creates Value Partnerships with provider organizations in order to help them

create value and optimize care delivery.

This white paper will discuss the successful implementation of a digital twin,

and the vital role Value Partnerships play in building a digital twin.

Introduction

Simulations are commonplace in many work environments.

They help to identify strategies that work, and possible

avenues for improvement, without the time and expense

of rearranging real-world enterprises.

Simulations are especially important for complex,

high-risk and/or technical tasks. Aircraft pilots train on

simulators all the time. Medical students perform tasks

on simulation mannequins so that they can identify issues

with a technique in a safe, controlled environment.

A digital twin is a four-dimensional model (here, time

constitutes the 4th dimension) of a care unit, multiple

departments or even an entire hospital. A digital twin

links the physical and virtual worlds, turning data into

actionable insights. This is a key facet of the emerging

manufacturing paradigm known as Industry 4.0.

A digital twin enables healthcare providers to move assets

around, reconfigure departments, and see the effects of

changes to the simulated environment. Because it models

so many dimensions, the twin produces a detailed look

into how the hospital is working. The effectiveness of a

healthcare facility digital twin can be enhanced by

leveraging powerful data sources like Real-Time Locating Systems. RTLS tracks the movement of equipment, files,

even individuals, and can refine the twin’s accuracy in

simulating processes. RTLS data can also enable use of

the digital twin to predict the availability of equipment

and resources, and can rapidly assess the real-world effect

of changes suggested by simulations.

Key uses for digital twins in healthcare institutions

There are three primary domains where digital twins can

be effective in healthcare:

- Predicting the outcome of a specific scenario; perhaps a reorganization of the patient flow and clinical workflow in a specific department.

- Evaluating, on a quantitative basis, the impact of different layout scenarios, such as re-arranging waiting areas or distributing and splitting waiting areas for specific modalities.

- Performing operational stress testing on a department or an entire hospital.

“Simulation modeling is common when designing robust

production lines in various industries” notes Nicolai

Gossmann, Senior Management Consultant at Siemens

Healthineers. “The same idea can be applied to designing

efficient and patient-centric hospital operations. So, for

example, what happens if we have a very high incoming

flow of patients in the emergency department? That’s

a very specific scenario, but you can also evaluate

the operational impact of increasing patient demand

in certain services and its additional effects on assets,

utilization, staff, and more. The more handovers there

are in [a patient’s] journey, the more opportunities there

are to improve,” according to Gossmann.

Digital twins in medical imaging

Medical imaging facilities are in high demand. In the US,

for example, there are more than 80 million CT scans

performed annually1, and that number is continually

increasing. This huge demand for diagnostic medical

imaging is a logistical challenge for providers around

the world. How can they make the best use of space,

equipment, and staff to provide the best possible care

for patients? The value of a robust, high-fidelity

simulation in this situation is clear.

“We’re tracking the patient from check-in to reports being

furnished to the patient,” says Helen Calvey, Country Lead

Ireland, Enterprise Services for Siemens Healthineers.

“All of that information is put into the model. We come

up with a very patient-centered workflow.” By building

a dynamic model of a care facility, a provider organization

can identify and spread best practices in order to improve

efficiency, patient experience, and quality of care.

Partnership: The key to successful development

A partnership with multiple parties, both internal and

external, is necessary to make the digital twin work.

Clinical staff, hospital workers, receptionists, appointment

schedulers, administrative team members, hospital

architects, and a committed, qualified technology partner

all play key roles in creating an effective digital twin.

And that technology partner has to be much more than

a vendor. Healthcare organizations are looking for

guidance on how they can optimize performance, expand

capabilities, and advance innovation to deliver higher

value of care. Siemens Healthineers has developed Value

Partnerships, enduring relationships with healthcare

providers that help transform care delivery and create

higher value. The Value Partnerships framework enables

us to bring complimentary services – like digital twins

and RTLS – to bear for our partners.

Case Study: Mater Private Hospital

Mater Private Hospital in Dublin is one of Ireland’s

leading institutions for radiologic imaging and cardiac

care. The desire to update the hospital’s imaging fleet

and to maximize efficiencies in departmental workflows

led to conversations about the benefits of digital twin

technology between hospital management and longstanding partner Siemens Healthineers. “We were

running late on some evenings in order to accommodate

the increasing demand for medical scans,” said Associate

Professor Paddy Gilligan, chief physicist at Mater Private.

“That wasn’t ideal from a staff or patient point of view.

”

Gilligan said growing the size of the radiology department

in order to meet increasing demand for services was

difficult for several reasons, including space in a confined

city center location, not to mention the overall cost.

Leadership at Mater Private recognized the opportunity

to make the right changes by creating a digital twin

of the radiology department and partnered with

Siemens Healthineers to make it happen.

The combined Mater Private Hospital / Siemens Healthineers

Value Partnership team built a representation of current

radiology operations while working to review current

layouts and identify potential improvements. A one-week

on-site assessment was conducted, including workshops,

stakeholder interviews, and process observation. In the

end a digital twin was created allowing the partners to

run different scenarios and identify the best use of

equipment, and pressure test a physical layout.

Gilligan said the four-dimensional view of the

department unearthed heretofore hidden insights.

“We verified data at every step to be sure it was realistic,”

he explained. “Once the model was available, we could

run scenarios and see the value-add to changes we

make. We could also see the impact changes to layout

and operations have on other parts of the hospital.

Improvements that previously took months or years

of trial and error can now be achieved in a matter of days

or weeks.”

Some of the identified improvement potential from Mater Private’s digital twin include:

- Shorter wait times for patients – a reduction of 13 minutes for CT scans and 25 minutes for MRIs.

- Faster patient turnaround (arrival to departure) which shrank to 28 minutes for CT cans and 34 minutes for MRI.

- Increased equipment utilization – MRI usage went up by 32 percent and CT usage went up by 26 percent.

- Lower staffing costs, including 50 minutes less MRI overtime pay per day.

The most important benefit the partnership can bring is to improve patient experience.

The Mater Private digital twin shows how long the patient will spend at each stage of

their journey through radiology. This allows planning for waiting times in each section

maximizing the use of space and optimizing the patient experience.

Future applications

According to Sören Eichhorst, Head of Healthcare

Consulting and Transformation for Siemens Healthineers,

digital twin applications provide great opportunities in

healthcare. “You can apply it everywhere – e.g. in

radiology, lab, for interdisciplinary pathways or for

non-medical processes.”

Indeed, digital twin technology can yield efficiency and

patient experience benefits for almost every part of a

healthcare enterprise, including:

- Prostate Cancer treatment, where the victim interacts with multiple departments and disciplines.

- Cardiology operations – Mater Private performs more than 6,000 angiograms annually.

- Intensive care units, where a four-dimensional redesign of the overall operation can yield improved quality of care and greater operational efficiency.

Creating a digital twin represents a break with

established ways of doing business, yet it pays

tremendous dividends. “It takes a lot of dedication and

commitment to sign up for a digital twin application,”

said Calvey. “A healthcare partner can bring the

knowledge and commitment where the technology

partner can bring the technical expertise; together we

can make this successful.

”

Value Partnerships leverage evidence-based solutions

and tailor them to the situation at hand. In this case,

using a digital twin helped Mater Private plan the

modernization and expansion of their radiology

department armed with foresight on how to optimize

workflows, capacity, and patient experience. It is a good

example of how Value Partnerships create value for all

stakeholders.

Conclusions

- Digital twin technology is most effective in the context of a partnership.

- A high-fidelity, effective digital twin requires collaboration among hospital executives, clinicians, administrative staff, the building architect, and the technology partner.

- The multi-disciplinary team should continuously evaluate the digital twin to confirm it is delivering robust insights and enhancing efficiencies in hospital operations.

- Technologies like RTLS can provide a rich data source and significantly enhance the effectiveness of a digital twin model.

- With RTLS, changes made to layout or workflow from the digital twin simulation studies can be quickly measured for impact and success.

- A digital twin can help plan changes or expansion to care units, and minimize the need for costly changes after a department has been reorganized.

- Value Partnerships enable healthcare providers to leverage the clinical and technology know-how of Siemens Healthineers to create value for stakeholders.

To learn more about Value Partnerships click here or go to https://www.siemens-healthineers.com/services/value-partnerships

or read the full Mater Private case study at siemens-healthineers.com/mater-private-case-study

Latest Articles

clinical decision support, Siemens Healthineers, CDSS, health care quality, medical error, Computer-Based Clinical Decision Support System, The value of digital twin technology, Digital twins in medical imaging

The Value of Digital Twin Technology