Upgrading selected touch surfaces to Antimicrobial Copper is a simple but effective measure that is shown to reduce costly infections, freeing up beds and clinical resources and improving patient care. After a very short initial payback period, significant long-term savings are possible.

How much are your clinical touch surfaces costing you?

Pathogens persist on standard clinical touch surfaces, creating reservoirs of infection that pose a risk to patients, staff and visitors. Touch surfaces made from Antimicrobial Copper alloy materials are proven to kill pathogens rapidly, in between cleans, helping to maintain a more hygienic environment and reducing the risk of healthcare-associated infections (HCAIs).

Key healthcare bodies around the world – EPIC3, ECRI Institute, AHRQ and CNESH to name a few – have recognised copper’s potential to boost infection control.

York Health Economics Consortium (YHEC) – leading global health economists based at the University of York – report a very short payback time (and significant ongoing savings thereafter) from upgrading key touch surfaces to Antimicrobial Copper.

HCAIs are very common and are a huge cost, financially and in terms of human life. Approximately 20% of ICU patients in European hospitals get HCAIs. In 2011, HCAIs affected 4.1 million patients, causing 16 million extra days in hospital. The direct clinical costs exceed €7 billion. 37,000 deaths were recorded as caused by

HCAIs, plus 110,000 deaths where HCAIs were a contributory factor.

Cleaning is not enough

Inert surfaces offer no protection against recontamination after cleaning or between touches. Even after cleaning, a surface may not be microbiologically clean. Contaminated surfaces present a significant risk in the patient environment. On solid Antimicrobial Copper surfaces, microbes are killed rapidly, 24/7, in between cleaning sessions and touches.

You can easily do more to improve patient safety

Hand hygiene, cleaning and disinfection remain the key pillars of infection prevention and control, but it is almost impossible to clean hands and surfaces often enough. Because Antimicrobial Copper kills microbes rapidly on contact, 24/7 and between cleans, it gives excellent supplementary and permanent protection and is a simple choice for safer touch surfaces in busy clinical environments.

Upgrade touch surfaces to Antimicrobial Copper

By choosing fixtures, fittings and other touch surfaces made from Antimicrobial Copper, you can continuously kill pathogenic microbes and provide an additional weapon in the fight against HCAIs. This novel approach involves no nanotechnology, surface coatings or costly maintenance. Touch surfaces are made from solid, eco-friendly metals with intrinsic antimicrobial properties that last the lifetime of the product.

Effective under typical indoor conditions

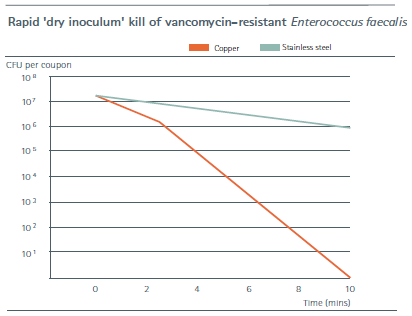

Copper is proven to have rapid broad-spectrum efficacy against the pathogens that cause HCAIs, including vancomycin-resistant Enterococcus, Influenza A(H1N1), Norovirus, Clostridium difficile, Pseudomonas aeruginosa and Staphylococcus aureus (MSSA, MRSA and E-MRSA). No pathogen tested has been able to survive on copper. Furthermore, microbial DNA/RNA is destroyed, so it is extremely unlikely that resistance to copper will develop.

Beware, as some products’ efficacy claims are based on test standards that are not appropriate to touch surfaces: JIS Z 2801 and ISO 22196 are ‘wet’ tests at raised temperature with results measured over 24 hours.

Antimicrobial Copper works under these conditions too, but is even quicker – just a few minutes – at typical room temperature and humidity

Proven under challenging clinical conditions

Compelling evidence from a three-year, three-centre randomised clinical trial in the US, funded by the Department of Defense, shows the link between reduced environmental bacteria and reduced infections after just 10% of touch surfaces in ICUs were upgraded to Antimicrobial Copper.

Business case shows rapid payback and ongoing savings

York Health Economics Consortium assessed relevant clinical evidence in western Europe and the US, and developed a cost-benefit model for Antimicrobial Copper upgrades. Users can input local cost data for fixtures, fittings and other medical equipment, along with care costs.

Default data entered by YHEC, based on their research and commercial costs, shows very rapid initial payback of a targeted upgrade to Antimicrobial Copper during refurbishment or newbuild construction.

Benefits of upgrading to Antimicrobial Copper Touch Surfaces

· Rapid and continuous broad-spectrum kill, between cleans

· No costly maintenance or special training needed

· Totally safe, ecologically sound

· Products available in a range of alloys with differing colours

· Antimicrobial protection lasts the lifetime of the products

· Recognised by key healthcare watchdogs worldwide

· Copper’s efficacy proven under typical indoor touch surface conditions

· Pathogens very unlikely to develop resistance to copper.

Antimicrobial Copper is an umbrella term for >400 copper alloys approved for Cu+ certified products, which are available in a range of colours including gold, silver, bronze and copper.

The upgrade team

Installations have already taken place around the world in more than 25 countries. In these hospitals, the importance of taking a multidisciplinary approach has been clear.

Finance Managers can download the YHEC model, enter their own data, and see how the cost of an installation, paid out of the estates or capital budget, is more than outweighed by the significant clinical savings earned against a care budget.

The Infection Control Team can review the scientific evidence and liaise with nursing staff to identify touch surface items of particular concern for different clinical areas.

Estates Managers can be reassured that products are available, affordable, durable, proven to work and are compatible with standard cleaning and disinfecting agents. They can be confident that products certified as ‘Cu+ approved’ are backed by an international industry stewardship scheme.

Finding more information

Your local Antimicrobial Copper specialists are ready to help you prepare your business case, assist your colleagues and source products and services.

Visit www.antimicrobialcopper.org to access scientific references, the YHEC model, case studies, the Cu+ Products and Services directories and to find your local Antimicrobial Copper contact.

Source & Image Credit : Copper Development Association